Supporting all Red Alert and Hyspan bearers

Supporting 50mm wide roll formed Boxspan bearers. Also come part of a designed kit sub-floor system.

Ideal for standard lengths of steel, rectangular hollow sections such as Duragal, Allgal and Supagal.

Supporting all hardwood timber

bearers

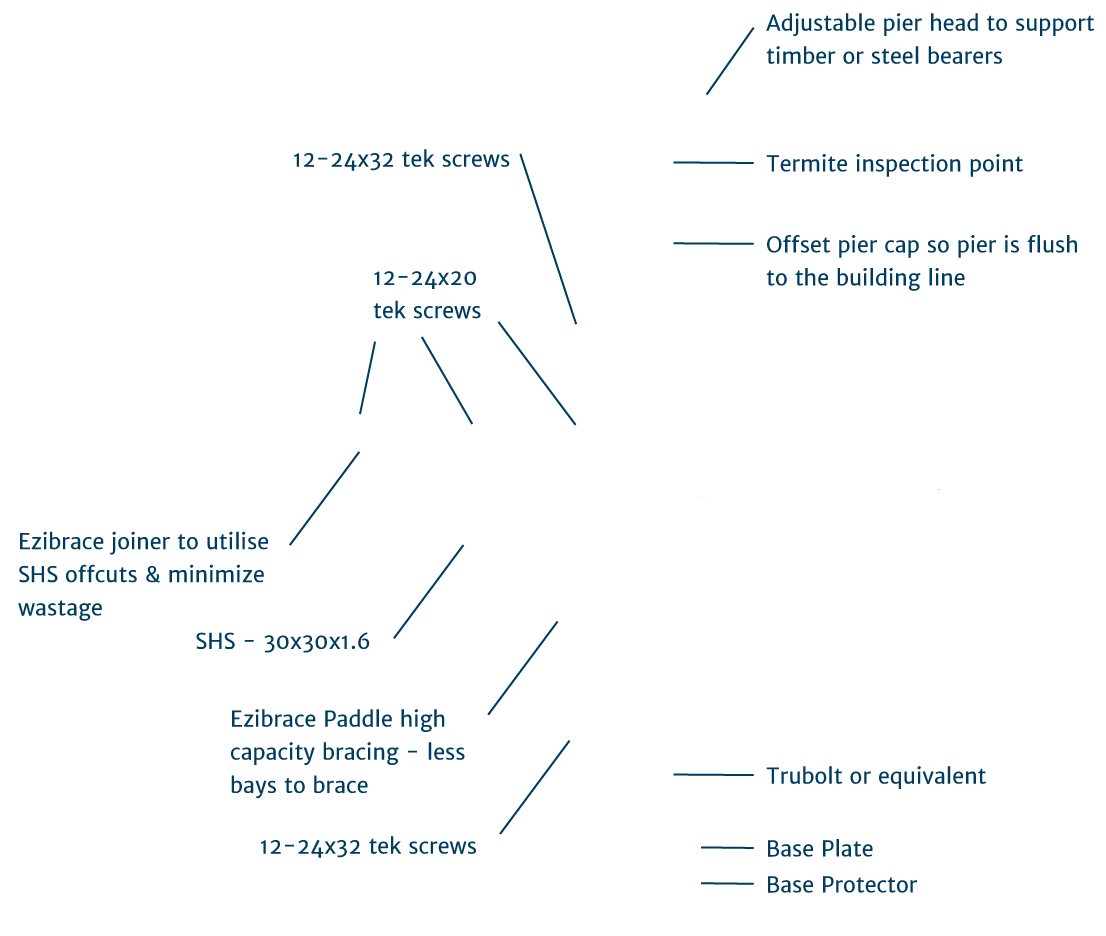

Designed so piers do not protrude outside the building line making it a neater finish for all trades.

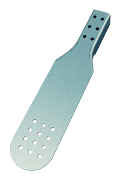

A high capacity bracing system that’s easy to install on low-set and high-set elevated floors.

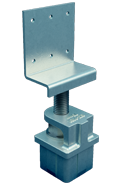

Ezipier heads and bases have been engineered in a variety of sizes to suit most site loads.

![]()

Cast iron designed top and base providing maximum strength and corrosion resistance.

True adjustability: Adjusting an Ezipier head is done by turning a nut not by removing bolts or tek screws.

Safe perimeter: Because Ezipier heads are designed for a flush finish there are no protruding components to hurt you when walking by.

Clear termite inspection point: Solid threaded rod – simple and easy to inspect, doesn’t interfere with cladding (note ant caps which can interfere with cladding are still only inspection points not “barriers”).

Affordable flexibility & convenience: The range of Ezipier heads have been designed to suit standard post sizes to handle most residential loads of up to 5m heights and for ease of purchase from local merchants.

Protection: Now you have the option to choose posts with higher protection when required to suit site conditions such as coastal areas.

Non-combustible: Can be used in bushfire prone areas.

Minimal wastage: With the Ezibrace joiner utilise small offcuts of SHS bracing tube without losing capacity.

Sloping sites: Piers and posts are typically used on uneven sites where it makes sense to have a cross bracing system like Ezibrace that allows for bracing posts of different heights.

Cut installation time in ½: We still can’t believe how easy we’ve made it! During onsite Ezibrace testing we found that most sub-floor bracing will take about half the time compared to systems we’ve used in the past. It’s quick to install and in high wind applications the Ezibrace system can be adapted to achieve a higher capacity so you need fewer bracing bays to resist wind loads.

High lateral bracing capacity: The design of the Ezipier paddle and joiner allows for a high number of screws if required by your engineer. This combined with the 30×30 SHS bracing tube can provide you a high capacity to restrain from lateral forces between 5°- 60° degree angles.

These are some recent tv shows and projects that feature Ezipier. From supporting decks to homes on sloping sites to high load commercial floors. Ezipier can also be used for re-stumping and rectification work to get floor back to level.

By breaking down the structure of the Ezipier and Ezibrace system you get a clear understanding of the function of each component and why this pier and bracing system is the easiest you’ll ever install.

For technical specifications and how components go together click on the links below.

Supports internal & external bearers 58mm-75mm in width.

Supports:

Timber LVL bearers

Steel “C” section bearers

Product codes/post sizes:

89mm EAPH-L

90mm EAPH-L

For internal & external bearers 50mm wide. Ideal for decks.

Supports:

RHS steel bearers

Boxspan deck bearers

Product codes/post sizes:

89mmEAPH10050

90mmEAPH10050

Suits 50mm wide bearers that are at least 150mm in height.

Supports:

Boxspan steel bearers

RHS steel bearers

Product codes/post sizes:

89mmEAPHSU9050150

90mmEAPHSU9050150

Internal & external double 2 x 50mm wide bearers.

Supports:

Boxspan steel bearers

RHS steel bearers

Product codes/post sizes:

89mmEAPHSU90100150

90mmEAPHSU90100150

Base plate to sit inside SHS posts. Available in 3 different sizes.

Suitable for:

90x90x2.0mm,

89x89x3.5mm SHS posts

Product codes/post sizes:

89mmEPB

90mmEPB

Select post size for your site loads. See Ezipier technical specs.

Coating options:

Galvanised Steel ZB135

Hot Dipped Galvanised

Available sizes:

89x89x3.5mm

90x90x2.0mm

Can be fixed to bearers or posts. See Technical specs for capacities.

Suitable for:

Sub-floor bracing &

other bracing applications

Product code:

EB30x30

For joining SHS bracing

tube off-cuts.

Suitable for:

30x30x1.6mm SHS

–

Product code:

EB30x30Joiner

30X30X1.6mm SHS bracing tube used between Ezibrace paddles.

Coating options:

Galvanised Steel ZB135

Hot Dipped Galvanised

Product codes:

30mmSHS-4m

30mmSHS-8m

Fixing Ezipier base plates to concrete pad footings.

Product code:

12x100WedgeAnchor

Alternative fasteners:

–

Self tapping screw for fixing Ezipier heads and bases to posts.

Product code:

S12-24×32

Alternative Fasteners:

–

Self tapping screw for fixing Ezibrace paddles/joiners to SHS.

Product code:

14-20×22

Alternative Fasteners:

M6-1.0x18mm

Designed specifically for use with adjustable Ezipier heads.

Product code:

EziSpanner

Compatible post sizes: 90x90x2.0 | 89x89x3.5

The Ezipier adjustable heads and bases have been designed to work easily with two common SHS (post) sizes. These can be readily sourced from steel merchants and many hardware and building supply outlets. This also gives you the flexibility to choose a posts size to match what you’re building from a deck close to the ground up to a high set house sub-floor.

You also have the added benefit of choosing between different protective coatings to suit the level of protection required for your environment. SHS posts (also referred to as tube) are available in two different coating finishes: Standard galvanised steel and batched hot-dip galvanising.

| Standard Galvanised Steel | Hot-Dip Galvanised | |

|---|---|---|

| Main Benefit | Available from most steel merchants & building suppliers. | Can achieve a higher level of protection for a project than galvanised steel. |

| Shelf product | Yes | No, Secondary process required |

| Stock Lengths | 1m, 2m, 4m, 8m | Job Lots |

| Lead time | Available for pickup Delivery 3-5 Days |

12-14 working days |

| Pricing | Mid level, higher than black steel | Qty/Project based |

| Paintable finish | Yes | No |

| Suitable for coastal areas | Refer to the table below | Yes |

| Level of protection | ZB135 or equivalent | HDG 390 - 1.6-2.0mm HDG 500 - 3.5-6.0mm (390g/m2 or 500g/m2 per side) |

| More Info | See Below | Link |

| Atmospheric corrosivity category | ||||

|---|---|---|---|---|

| Designation | C1 | C2 | C3 | C4 |

| Description (Refer to AS 4312 and ISO 9223) | Indoor dry Air-conditioned (not ventilated externally) | Most areas of Australia beyond 50 km from the sea but can be as close as 1 km from relatively sheltered waters. | In coastal areas with significant surf, this area extends from around 1 km to 50 km, varying significantly with winds, topography and vegetation. Around sheltered bays it extends from around 50 m to 1 km from the shoreline. | Occurs mainly on the coast in areas with rough seas and surf, extending from around 300 m to 1 km inland. Around sheltered bays it extends up to 50 m from the shoreline. |

Application |

||||

| Components inaccessible for maintenance | ||||

| Roof framing system – unventilated | A | A | C | C |

| Roof framing system – ventilated | NA | B | C | D |

| Wall framing system – unventilated | A | A | C | C |

| Wall framing system – ventilated | NA | B | C | D |

| Floor bearers and joists including intermediate floors – unventilated | A | A | C | C |

| Floor bearers and joists – ventilated | NA | B | D | D |

| Decking/balcony – integral (eg cantilevered) | NA | C | D | D |

| Ceiling battens | A | C | C | |

Components accessible for maintenance |

||||

| Roof battens | NA | B | C | C |

| Stumps and piers supporting main building | NA | C | C | C |

| Decking/balcony – independent of main structure | NA | B | C | C |

| Verandah beams and rafters | NA | B | C | D |

| Verandah posts and stumps | NA | B | C | D |

| Carport rafters and beams | NA | C | C | D |

| Carport posts | NA | B | C | D |

| Lower storey unlined eaves and pergola rafters and beams | A | B | C | D |

| Pergola posts | NA | B | C | D |

| Hot dip metallic coated strip AS 1397 | ||||||

|---|---|---|---|---|---|---|

| Protection designation (Refer to Table B1) | Zinc | Aluminium/Zinc | Aluminium/Magnesium/Zinc | Open sections Zinc/Aluminium AS/NZS 4791 | Hollow sections either: Hot Dipped Galvanised (ZB, ILG, HDG) or Electroplated (ZE) - Zinc AS/NZS 4792 AS 4750 | Post fabrication hot dip galvanised Zinc AS/NZS 4680 |

| A | Z275 | AZ150 | AM150 | IZA75 | ZE50/50 | HDG320 |

| B | Z275 | AZ150 | AM150 | IZA75 | ZB100/100, ILG100 | HDG320 |

| C | Z275 | AZ150 | AM150 | IZA75 | HDG300, ILG140, ZB135/135 | HDG320 |

| D | Z450 | AZ150 | AM150 | IZA200 | HDG300 | HDG320 |

It’s early days for our new distribution model so if your area isn’t covered by one of our distributors please call us for pricing or to place an order. (Distributor list updated 17/5/2017)

Ezipier & Ezibrace are products manufactured by Spantec Systems, specialists in flooring systems.

P: 02 4860 1000

E: sales@spantec.com.au

A: 17 Drapers Road, Braemar NSW 2575

Building Differently From The Start

If you remember the days, like we do, when brick piers were the norm you’ll understand how far subfloor supports (stumps or piers) have come. At Spantec Systems not only do we make the adjustable Ezipier and Ezibrace but we also invented the whole concept of using a steel pier to replace a brick pier more than 20 years ago.

The steel Ezipier was then available only as part of our complete designed Boxspan steel sub-floor system. But now we’ve made the decision to unlock some of our offering and give the opportunity for anyone who builds sub-floors to use our piers and bracing components. So no matter what type of bearers and joists you’re using; LVL’s, hardwood, steel RHS and “C” sections there is an adjustable pier head to suit.

Other trademarks on the site are the property of their respective owners as follows: MAXI-TUBE® and Allgal® are registered trademarks of Orrcon Steel, Red Alert® is a registered trademark of Tilling Timber, Hyspan® is a registered trademark of Carter Holt Harvey Woodproducts Australia, Duragal® and Supagal® are registered trademarks of OneSteel Trading.